1. Description of Sulfuric Acid Cooler Without Anodic Protection

The high silicon SS alloy sulfuric acid cooler is constructed from a special high silicon material that offers excellent castability, hot and cold processability, and welding performance. It is highly resistant to high temperatures and strong sulfuric acid. This material has been effectively utilized in the production of valves, pipes, and equipment for drying and absorption systems in sulfuric acid plants.

Material Characteristic

| Alloy Designation | Tensile Strength | Yield Strength | Elongation Rate |

|---|---|---|---|

| 3.0mm plate rolling direction | 746.39Mpa (σb MPa) | 337.00Mpa (σ0.02 MPa) | 59.00% |

| 3.0mm plate vertical rolling direction | 757.07Mpa (σb MPa) | 333.50Mpa (σ0.02 MPa) | 55.90% |

| 700Si-<20mm plate | 540.00Mpa (σb MPa) | 240.00Mpa (σ0.02 MPa) | 50.00% |

| SX-Deformable material | 490-800Mpa (σb MPa) | >220.00Mpa (σ0.02 MPa) | >45.00% |

| ZeCor-ASTM A240 standard | >=538.00Mpa (σb MPa) | >255.00Mpa (σ0.02 MPa) | >=30.00% |

| ZeCor-Typical data | 800.00Mpa (σb MPa) | 379.00Mpa (σ0.02 MPa) | 53.00% |

Corrosion rate (mm/a)

| Test Temperature (℃) | Duration (h) | 93%H2SO4 | 98%H2SO4 |

|---|---|---|---|

| 60 | 168 | 0.00083 | 0.00035 |

| 80 | 240 | 0.00105 | 0.00052 |

| 100 | 72 | 0.0045 | 0.0020 |

| 120 | 73 | 0.00873 | 0.00228 |

| 150 | 74 | 0.026 | 0.0025 |

| 200 | 100 | 0.636 | 0.063 |

2. Features of High Silicon SS Alloy Sulfuric Acid Cooler

a) When selecting materials for the accessories that come into contact with high-concentration acid in the high silicon SS alloy acid cooler, the principle is to use high silicon SS alloy or general SS lining with high silicon SS alloy. For the accessories that come into contact with cooling water, carbon steel or other SS can be used based on different water quality requirements.

b) The high silicon SS alloy acid cooler is manufactured in strict accordance with GB151 and relevant heat exchanger standards. For making the tube plate, forged pieces of high silicon SS alloy are selected. When making tube sheets, flanges, and other accessories, the thickness should have a safety coefficient based on strength and stiffness. The pipe holes are drilled using a digitally controlled drill to ensure accuracy and reduce the risk of damage to the pipe bundle during installation.

c) The manufacturing process for the tube plate and heat exchange pipe involves “welding after expansion” to meet the high sealability requirement for the sulfuric acid cooler and avoid crevice corrosion.

3. Benefits of High Silicon SS Alloy Sulfuric Acid Cooler

a) Excellent corrosion resistance

b) No anodic protection is required

c) low requirement maintenance

d) high heat transfer efficiency and continuous operation

e) Highly customizable, suitable for actual process condition

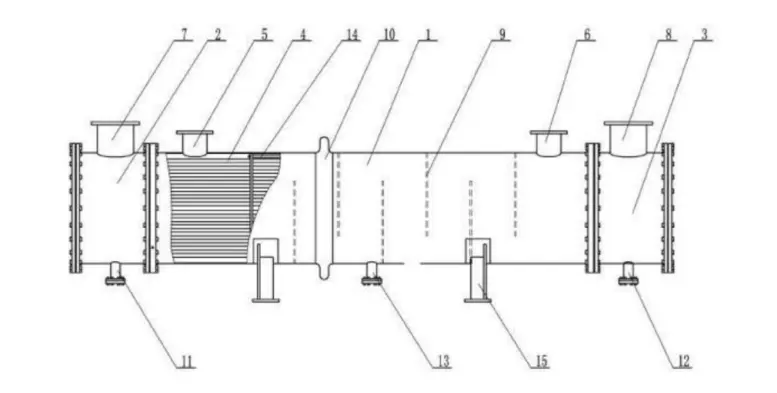

4. Structure of High Silicon SS Alloy Sulfuric Acid Cooler

The acid cooler consists of a shell (Shell 1) connected to the front and back channel boxes (2 and 3), housing a heat exchange pipe bundle (4). Inlet and outlet pipes (7 and 8) are positioned at both ends of the shell. The space outside the heat exchange pipe bundle is equipped with a baffle plate (9) to enhance liquid flow. An expansion joint (10) is installed above Shell 1.

All components in contact with high-temperature, high-concentration acid are made from a durable, corrosion-resistant alloy. The design allows for the use of special steel materials enhanced with rare earth elements, eliminating the need for an anodic protection system, thus minimizing associated issues.

The system can designate either a chamber as a cooling chamber or an inter-pass chamber, optimizing functionality while reducing costs. Benefits of this design include improved heat exchange performance, ease of installation, stable operation, and a smaller footprint.

5. Why Choose High Silicon SS Alloy Sulfuric Acid Cooler

Material Choice: Utilizing high-silicon stainless steel for the heat exchange tubes enhances corrosion resistance and improves heat transfer efficiency.

Design Compliance: The acid cooler adheres to the standard design requirements of a tube-and-shell heat exchanger, employing a flow route analysis method and incorporating a cross-flow fraction rate.

Vibration Considerations: Vibration can exacerbate corrosion and mechanical damage in the heat exchange tube bundle, as seen in anodic protection systems. The design of the high-silicon stainless steel acid cooler accounts for vibrations by avoiding a fully lined tube structure. The spacing of inlet and outlet baffle plates is wider than that of middle baffle plates, while still adhering to maximum spacing limits without support.

Flow Route Design: The flow route can be customized according to user needs and process requirements. To minimize scaling issues, it’s advised to direct cooling water through the pipes and sulfuric acid through the shell. Additionally, a leptosomic structure is recommended to maximize the heat exchange area.

Contact us today for a free quote!

You may also be interested in the Metso sulfuric acid cooler: Edmeston SX® sulfuric acid coolers – Metso

377015863 –

The ultimate solution for sulfuric acid cooler with anodic protection