1. Introduction to high-efficiency sulfur gun

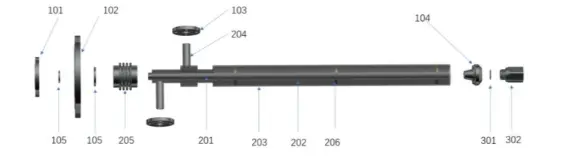

The core component of the LGS3 high-efficiency sulfur gun is the spray nozzle which adopts the technology combination of atomization spray nozzle, two-stage molten sulfur speed increase, and mechanical forced atomization. 75% of atomization particles are less than 20µm and the atomization angle is 40~43°. By adopting Laval nozzle technology, the flow rate of molten sulfur can be increased by 4~6 times. The high-efficiency sulfur gun is equipped with the GH3 high-efficiency nozzle without resistance along the flow channel and local resistance, providing a stronger anti-blocking ability. The gun uses a uniform distribution ring for steam insulation, ensuring consistent temperature of the gun body, and solving the problem of gun body bending.

2. High-efficiency sulfur gun performance

Name: High-efficiency sulfur gun

-LGS3A:1~5t/h is used at acid waste cracking, hydrogen sulfide to acid conversion, and sulfonation units.

-LGS3B:5~10t/h for the elemental sulfur burning unit, single gun 200kt/a.

-LGS3C:7.5~15t/h for elemental sulfur burning unit, single gun 350kt/a.

Maximum operating temperature: 1100℃.

Maximum operating pressure of molten sulfur pipe: 2.5Mpa.

Maximum operating pressure of jacket pipe: 1.6Mpa.

3. High-efficiency sulfur gun strengths

a)Largesulfuric acid plants can reduce the number of sulfur guns installed, decrease investment in molten sulfur pipelines and instruments, reduce the space used by sulfur furnaces, and minimize the installation and removal work of the sulfur gun.

b)High atomization efficiency effectively increases the utilization rate of sulfur furnaces, prevents molten sulfur combustion at the bottom of the sulfur furnace, and protects the sulfur furnace from sublimation sulfur corrosion and internal sulfur sublimation.

c)Theultra-wide atomization adjustment range allows for stable atomization combustion and is suitable for large, medium, and small-scale plants.

d) The high-efficiency sulfur gun adopts layered combustion technology to prevent the furnace temperature from exceeding 1150℃, effectively ensuring the safe operation of the equipment.

e) The high-efficiency sulfur gun is resistant to bending and helps users achieve long-term operation.

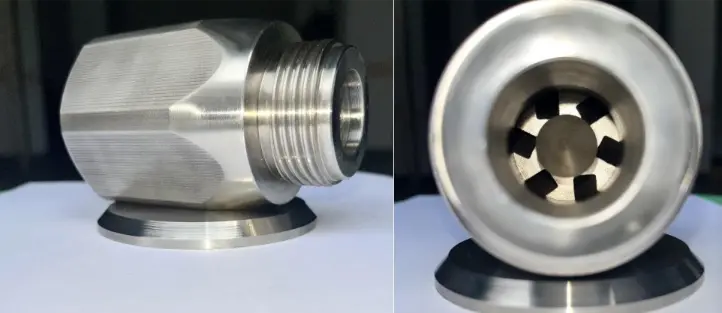

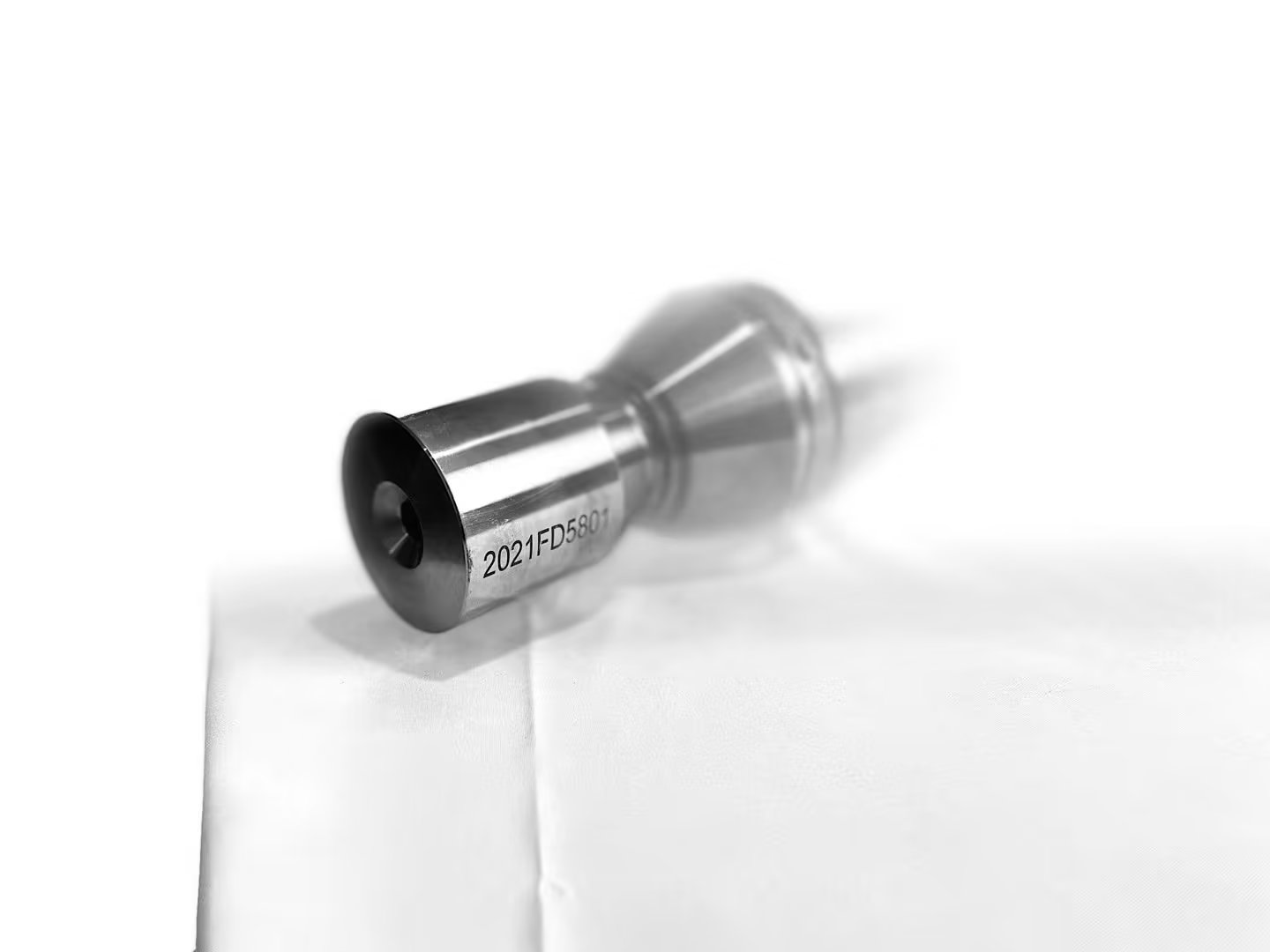

4.The Nozzle

The nozzle is made of heat-resistant 310 stainless steel material. Its atomization principle utilizes a two-stage Laval mechanical forced spiral atomization technology, and there is no molten sulfur dripping in the negative pressure zone at the nozzle. The flow adjustment ratio is 1:3, and the pressure adjustment ratio is 0.4~1.3MPa. A starting of 0.4 Mpa can achieve effective atomization, and an atomization pressure of 0.9MPa can meet full load requirements. The nozzle flow channel has a cross-sectional area of 294mm2 with six 7mm×7mm flow channel holes, providing strong anti-particle blockage capability. 75% of the atomized particles are ≤20µm. The solid core atomization cone effectively increases the utilization rate of sulfur burners. The high-efficiency nozzle and the nozzle sealing seat are connected by threads, with the sealing gasket being a high-temperature resistant metal gasket, effectively solving the problem of sealing leakage caused by solving by thermal expansion during production restart after shutdown, and making maintenance and disassembly more convenient. Overall, the high-efficiency sulfur gun and nozzle system provides efficient atomization of molten sulfur, improving the performance and operational efficiency of the sulfur furnace in sulfuric acid plants.

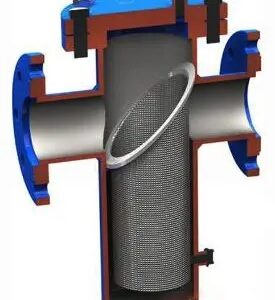

5. How it works?

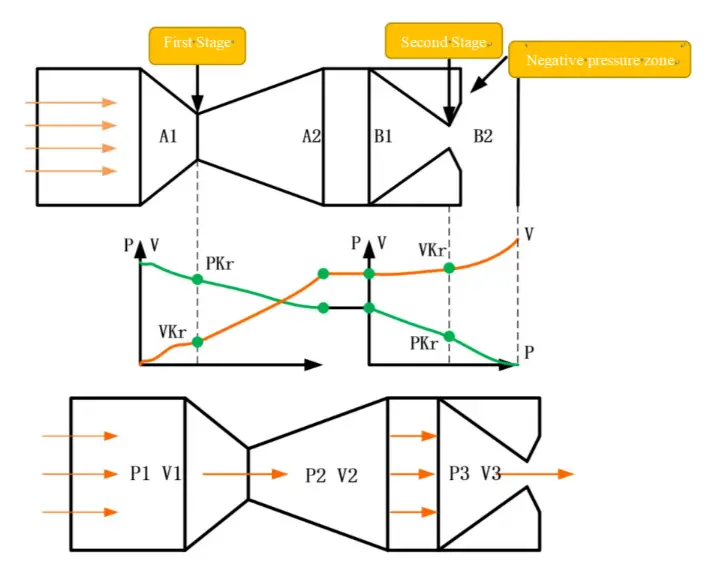

The high-efficiency nozzle utilizes a two-stage Laval design to effectively spray molten sulfur. Here’s how it works:

1. Sulfur Acceleration: The front of the nozzle narrows, creating high-speed flow. This design helps to accelerate the molten sulfur as it moves through.

2. Two-Stage Process: First, the sulfur accelerates in the first stage, then continues to speed up in the second stage. When it exits the nozzle, it forms fine, atomized particles.

3. Pressure Conversion: The shape of the nozzle changes the static pressure of the sulfur into dynamic pressure, allowing for better spraying and atomization.

In summary, the two-stage Laval nozzle design of the high-efficiency nozzle transforms molten sulfur into fine particles. This boosts spraying efficiency and improves sulfur combustion, leading to a more stable and effective production process. This design makes the combustion process more efficient.

Click here to receive a complimentary quote today!

You may also be interested in other articles about sulfur gun

377015863 –

A useful item for use in the sulfuric acid plant.